Mizsepack | Öntapadó címke, fólia és műbél felülnyomás, konfekcionálás

Profile of Our Company

Our company has 3 main market segments:

– the finished artificial intestine

– the self-adhesive label

– and the foil label supplier.

The vast majority of our customers are domestic companies, but our participation in the export market is also increasing, which is due to our continuous commercial activity and modern machinery.

We consciously designed our fleet in such a way that we can serve small, medium and large market needs.

Self-adhesive labels (colloquially known as stickers) can be made for all industries, e.g. food industry, chemical industry, cosmetic industry, pharmaceutical industry, etc.

The foil label is used for bottling mineral water and soft drinks, as well as packaging chocolate and dairy products.

Ready-made casings are mainly used by meat and dairy companies and pet food manufacturers.

Our sales exceed HUF 5 billion.

Customer Relations

Due to the technology the most significant customers of Mizsepack are from meat and food industry, however we are in touch with several other well-known companies operating in other field of activities. The basic aspect of our way of thinking is that the customers’ demands are always considered to be primary and our activity must be adjusted to it. An important element of our customer service is that both artwork processing and printing form making are carried out by our own team. The existing 4 work stations are able to receive either PC or Macintosh graphical data files, in this way the pre-press preparation is quick and we can implement the required modifications locally. We also undertake designing in case of special demands. Our wide range of knowledge on the area of raw materials and printing makes it possible to find the answer for every arising question and to offer the most optimal solution for our partners.

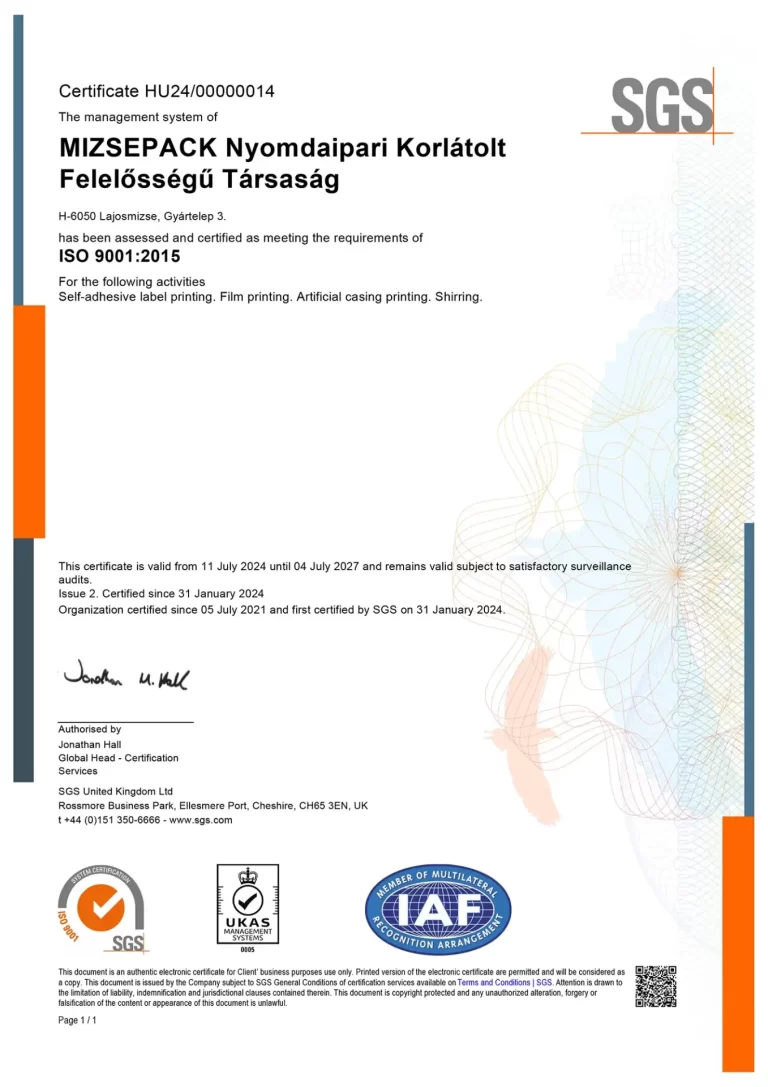

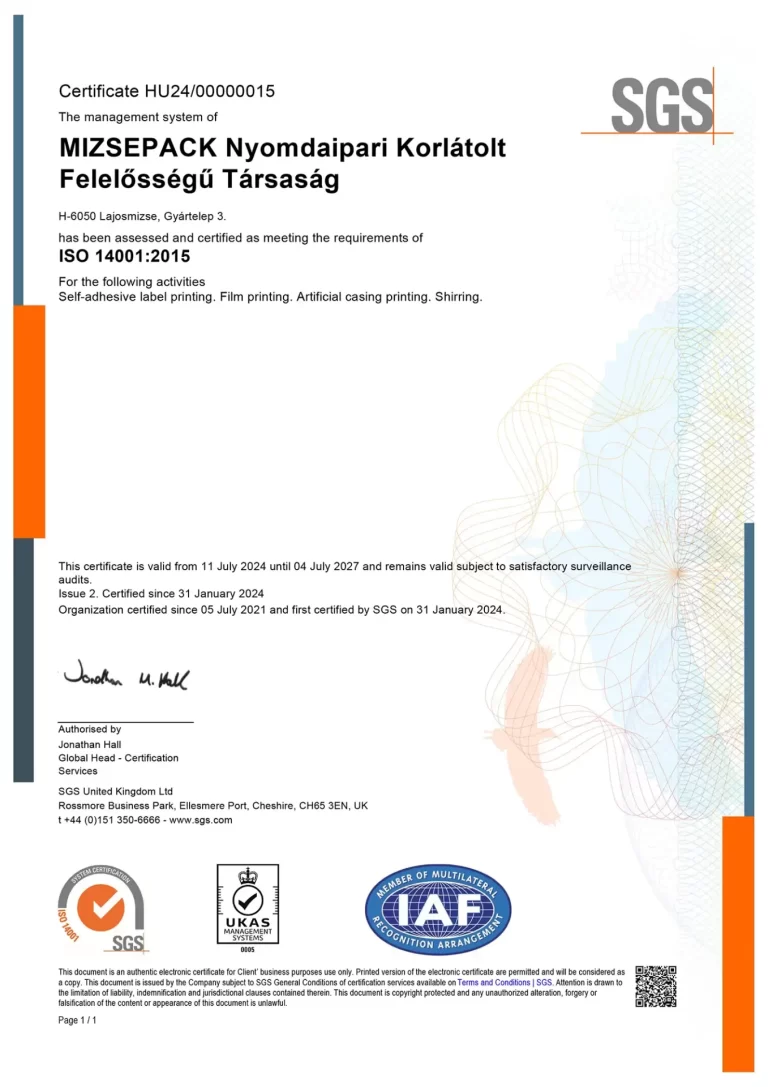

Quality

- We believe that our customers satisfaction is the result of the customer-centred way of thinking. The primery aim of our quality and enviroment-centered corporate strategy is to provide effective service to our customers and to meet the challenges of sustainable development.

- As a proof of our commitment the quality management system is certified according to ISO 9001:2015 standard, the enviromental management system is certified according to ISO 14001:2015, together with HACCP food industrial quality assurance system. We aim at extending our market position, increasing the international acknowledgement and developing the condition of our natural enviroment by continuous customer-centred developments.

Dun & Bradstreet, Europe’s largest company certification, gave our company a AAA certificate.

The financial risk of developing a business relationship with the enterprise is extremely low i.e. it is one of the exceptional Hungarian companies that have complied with the strictest conditions set by the Dun & Bradstreet international rating system.

Machine Park

A ltd. its machine park is designed according to the three main areas of activity. We have 7 printing machines at our disposal for the production of products, of which 3 only print synthetic labels, and 4 print self-adhesive and foil labels. Substitutability was an important aspect in the design of the machine park, since in the event of any error, we can immediately make it on the other machine. Our own maintenance team quickly solves the problem that has arisen, if necessary with the involvement of the machine manufacturer’s specialists. Our machines work in three shifts, we solve the satisfaction of the additional demand that arises by reorganizing the work schedule.

| Casing Printing Machines | Color Number | Width | Production Technology |

| TMB | 8+8 | 650 mm | Alcohol and UV Flexo |

| TMB 2 | 6+6 | 410 mm | Alcohol and UV Flexo |

| Nilpeter F-200 | 7 | 200 mm | Water Flexo |

| Casing Printing Machines | Color Number | Width | Production Technology |

| MPS EP410 | 7+Lakk | 430 mm | UV Flexo |

| Nilpeter F-2400 | 6+Lakk | 218 mm | UV Flexo |

| HP Indigo WS6600 | 7 | 330 mm | digital |

| Durst TAU 330 RSC | 5 | 330 mm | digital |

| Film Printing Machines | Color Number | Width | Production Technology |

| Gidue Master Combat | 7+Lakk | 430 mm | UV Flexo |

| SOMA Optima | 8 | 880 mm | alcohol |

| Finishing Machines | Width | Production Technology |

| Flexor 440B | 440 mm | 10 Tracks |

| Rotoflex S-1000 | 200 mm | 4 Tracks |

| ABG Digicon Series 2 | 330 mm | 9 Tracks + 1 color + stanc | HFV-650 | 650 mm | 10 Tracks |

| Flexor 440C | 440 mm | 10 Tracks + stanc |

| Pluto III. | 1100 mm | 18 Tracks |

SHIRRING MACHINES The artificial casings are folded using an oily and wet process. Caliber:28~120 mm Shrinkable length: 20 m, 25 m, 30 m, 40 m

History

Mizsepack Printing Ltd. became an independent company in 1990. It’s legal predecessor as the headquarter of Bács-Kiskun County Printing House began its operation in Lajosmizse in 1962. Its activity included printing of books and university lecture notes, as well as cliché making, later production of board games and artificial casings.

Simultaneously with the change of ownership, reorganization of the company also started in 1992 which was accompanied by continuous development and deliberate framing of market policy. Due to the planned developments the technology of artificial casing printing was updated continuously, so nowadays Mizsepack is the market leader on the area of artificial casing confectioning, having more than 50% market share. Under the effect of being present on the market and having feedback, we started the production of self-adhesive labels in 1994, which placed Mizsepack to the second most significant position on the market by 20% market share. Nowadays our turnover reaches 3 billion HUF by the production of artificial casings, self-adhesive labels and printing foils and we are proud that we cope with almost all the tasks on our own.

Our constant aim is to form such a quality and price value proportion, keeping the customer interests in mind, which ensures continuous customer satisfaction, professional development and safe jobs for 115 workers of Mizsepack.

2023

Qualifications

- Our company has obtained certification according to the FSC® standard.

- OPTEN Kft. gave our company an “A” certificate.

2023

2022

Machine Purchase

- Label stripping machine equipped with Flexor 440C tool,

- Pluto III. foil cutting machine

- Commissioning of Durst TAU 330-RSC digital printing press.

2022

2019

Investments, Developments

- Construction of a new plant hall extension of 580 m2.

- Commissioning of the new Soma Optima high-performance solvent flexo printing press.

- Commissioning of a new central counter-pressure cylinder TMB artificial casing press.

- Installation and commissioning of a 500 kW solar park.

2019

2018. november 24.

Death of József Gór, the main owner of Mizsepack Kft.

2018. november 24.

2017

Developments

Starting to use digital printing form making.

Buying a new, high performance shirring machine.

József Gór, the company founder and CEO died in november.

2017

2014

Machine Procurement, Developments

- Buying a new HP Indigo WS6600 digital printing machine.

- Buying a new ABG Digicon Series2 machine.

- Imroving air ventillation system.

2014

2011

Machine Purchase

- Investing in a new and modern 8+8 colour TMB flexo printing machine.

- Buying a new and modern 8 colour UV flexo GIDUE Master Combat printing machine.

2011

2010

Investment, Machine Purchase

Site expansion Installation of Flexor slitting and rewinding machine.

2010

2009

Machine Purchase

Putting into service the Newfoil foiling machine.

2009

2006

Machine purchase, New Business

- MPS-EP410 új, korszerű 8 színes UV flexo nyomógép beszerzése.

- Fóliacímke gyártás elindítása.

2006

2003

Qualification

Introduction of ISO 14001:1997 environmental management system and HACCP food¬safety system, successful transfer to ISO 9001 :2001 standard.

2003

2002

New Business

Starting the curving of artificial casings.

2002

2001

Investment

Moving to the present, modern location, built as a greenfield investment.

2001

1998

Machine Purchase

Investment of Nilpeter UV machine.

1998

1997

Qualification

Introduction of ISO 90021994 quality assurance system.

1997

1994

New Business

Starting the production of self-adhesive labels.

1994

1992

The First Step, New Business

József Gór purchased the Ltd. from Printing House Co.

Starting the shirring of artificial casings

1992

1985

Antecedent

Starting the printing of artificial casings.

1985

1962

Antecedent

Bács-Kiskun Country Printing House (legal predecessor of Petőfi Printing House Co.) founded its headquarter in Lajosmizse

1962