Mizsepack | Öntapadó címke, fólia és műbél felülnyomás, konfekcionálás

Self Addhesive Label Printing

We are able to provide self-adhesive labels for all purposes, up to a size of 415*609 mm, printed in total of 8 colours. Printing is done in UV flexo and water flexo technology. We have 3 printing machines capable to handle three different widths to ensure economical production. Labels are available printed on paper, plastic, thermo, metal steamed or even safety base. Opportunity is open for surface enhancement such as UV-varnishing, mat varnishing, laminating with shiny or mat foil, foil stamping with shiny or mat foil, or embossing. Labels are delivered in webs on reels of 25 – 40 – 76 mm in size. Unlike the practice generally prevalent in the industry, we keep substantial stocks of the most used raw materials as a result of which we are able to undertake assignments with short delivery time, if needs be even within 24 hours.

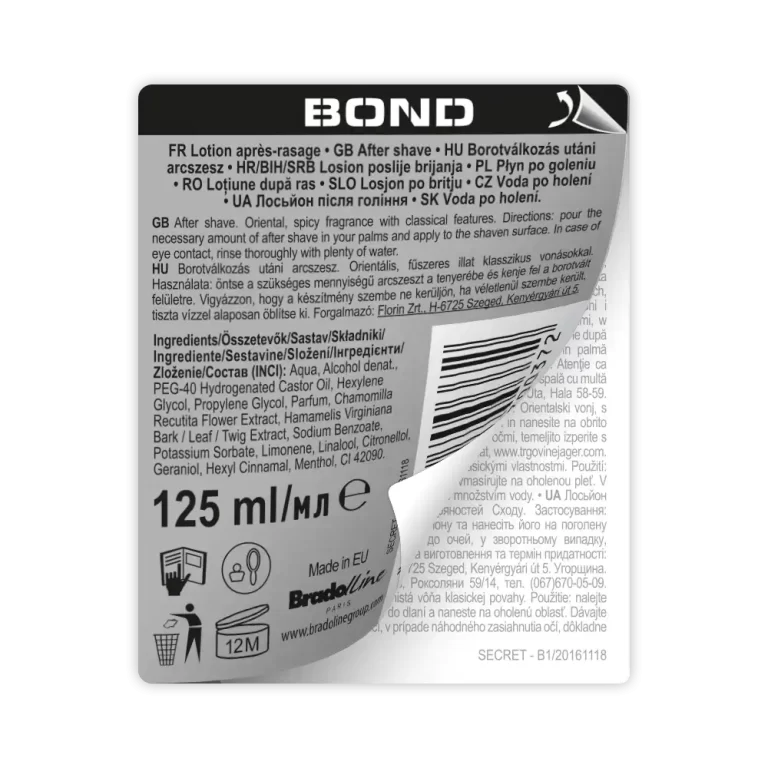

Multi-layer Label Printing

Current market demands require that customers are to be informed with the most possible information being printed on the smallest possible place, which is a trend to be followed also in the field of label printing. To satisfy this requirement Mizsepack Kft. created its multi-layered label with the name “label on label” consisting of 2 or 3 resealable sides. Based upon the size we can provide our partner with the die-cut plan, for which their graphic designer can create the graphics. Multi layered labels are most often made of plastic base in order to prevent the different layers from sticking to each other.

Variable data label printing

We frequently face the demand that each product should be supplied with different labels with varying information, or even an unique label for each product is ordered. This most often happens when a company refers to its other products on one product with the use of a QR code, or if on promotional campaign product different codes are to be printed on each product. We offer several options to print varying information on different labels. It can be executed on digital printing press, that is, on each label there is a different graphic, text, code or even a serial number. A template can also be used if the requirement is that different information is to be printed on certain batches of labels, e.g. information should alter after every 25 pieces. It is also possible to print a serial number with pre-programmed content. Based upon requirements from the customer we are happy to make recommendations for the execution. We can also undertake the printing of variable information on self-adhesive labels and foil labels.

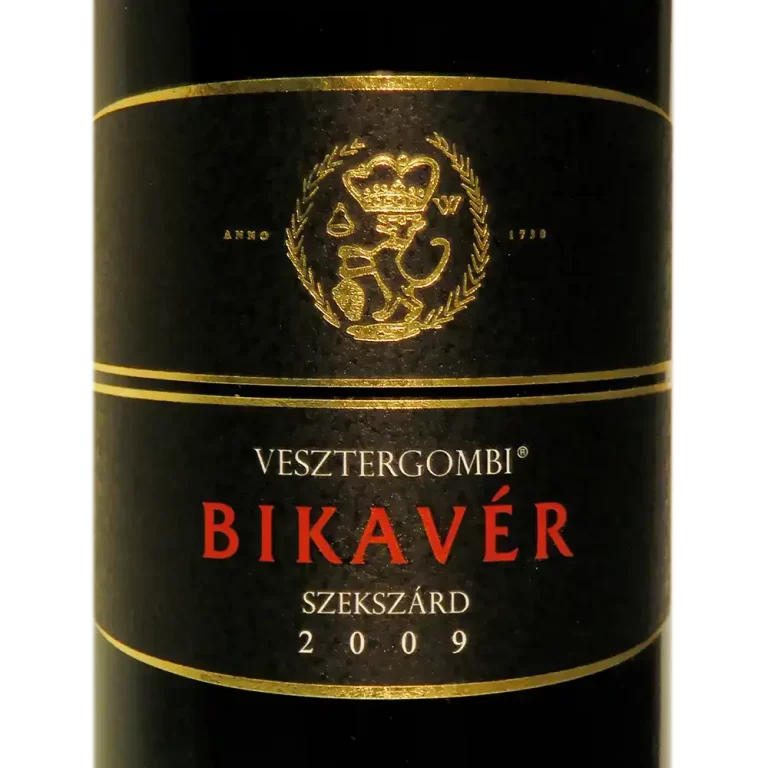

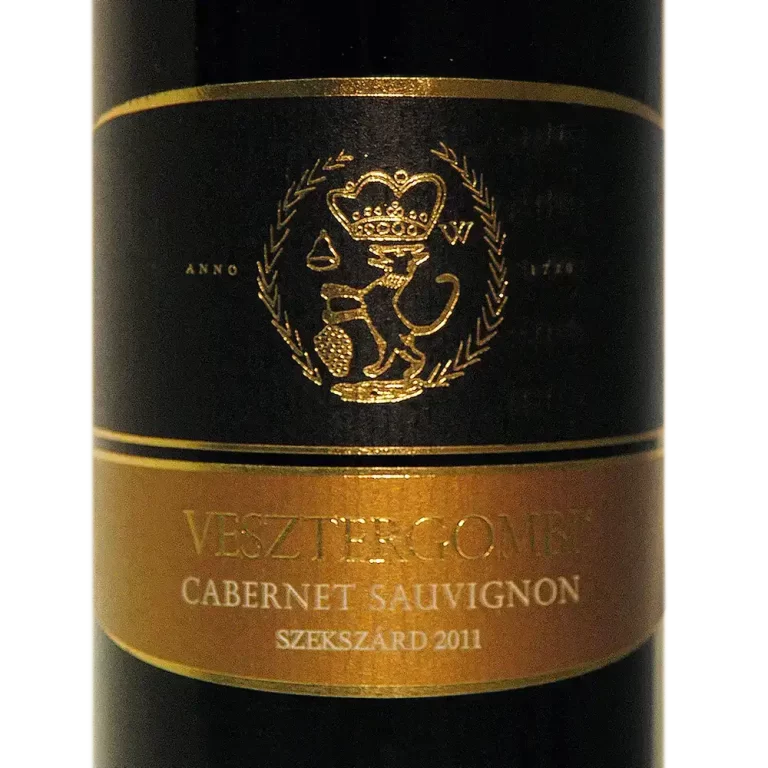

Embossing

One of the best solutions for enhancing the surface of printed products is embossing, or foil stamping. For this procedure we use different but most often gold or silver coloured stamping foil that enables us to create unique decoration elements. It is an elegant solution most often used on labels for wine bottles and beauty products. The procedure is done either cold or hot. The difference between the two processes is that at hot stamping a metal (most often copper) press sheet is needed which is heated to 120 C° and used for “ironing” the foil onto the surface of the label. By applying this method more contoured edges and finer patterns can be created. When applying the cold process, we use traditional press template (plate) that is used to administer glue that dries to UV light onto the surface and this glue will keep the foil on the surface of the foil label. This technology is more simple and can be executed on most of the web fed printing presses, however the contours of the foil are not so exact and clear cut.

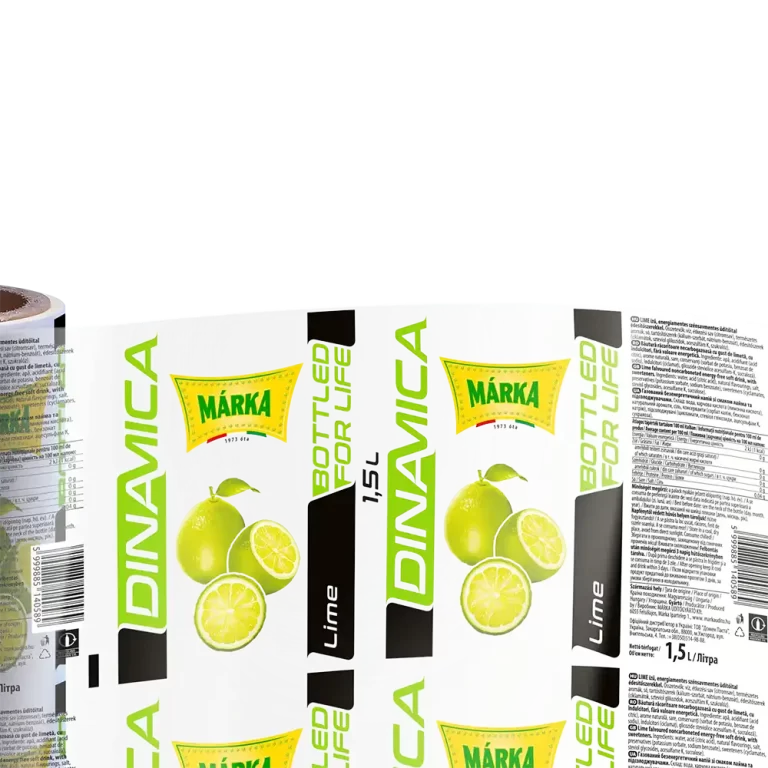

Film printing

There is hardly any exception among mineral water bottles where the label is not printed on foil and the tendency is continuously expanding. Should you wish to use the same, Mizsepack Kft. is able to provide you with such labels printed in 8 colour flexo and digital printing on white, transparent or even metal steamed foil. By applying the special cover layer, our labels can also be used efficiently on high performance (even 30.000 bottles/hr) labelling machines. The smallest label height is 30 mm, while the largest may be up to 760 mm. We use two high capacity UV flexo, as well as 1 digital printing press for producing such labels. Following printing, labels are cut (slit) with 2 foil cutting machines, and then in turn labels are rolled up in continuous reels with even sides free of any waves or static charge.

Casing Printing

Our new printing press offers our partners products printed in 8+8 colours that is perfectly fit to satisfy all market needs. We are able to print all types of casings, that is, beyond the PA casing special casings like FIBROUS, collagen, celluloid or any other special types of cases can be printed as UV inks, as well as solvent and water based inks can also be applied. We can offer edge to edge printing possibility in case of PA casing, when you are not able to see the basic color of the casing after filling.

Casing shirring

Mizsepack Kft. was among the very first in the Hungarian market to offer this service, and ever since, serves its partners with standard high quality, and as well makes it easy for its partners to process casings in the production plants. Besides the well-tried 30 meter worms – in certain cases – we also provide our partners the possibility to have this product in shorter versions, or as it is nowadays more and more typical in longer versions.

Casing curving

In Hungary and as well in the region we are unique in providing curving services for our partners. By applying curving, products in casing are given a unique shape that makes such products look more spectacular and attractive for customers. When this is coupled with the opportunity of printing with 8+8 colours, which is done in Mizsepack Kft on a brand new printing press, success of the meat industry product is almost certain and greatly contributes to the saleability of the product, which in turn increases the sales thereof.